ROBOT WELDING

ROBOT WELDING

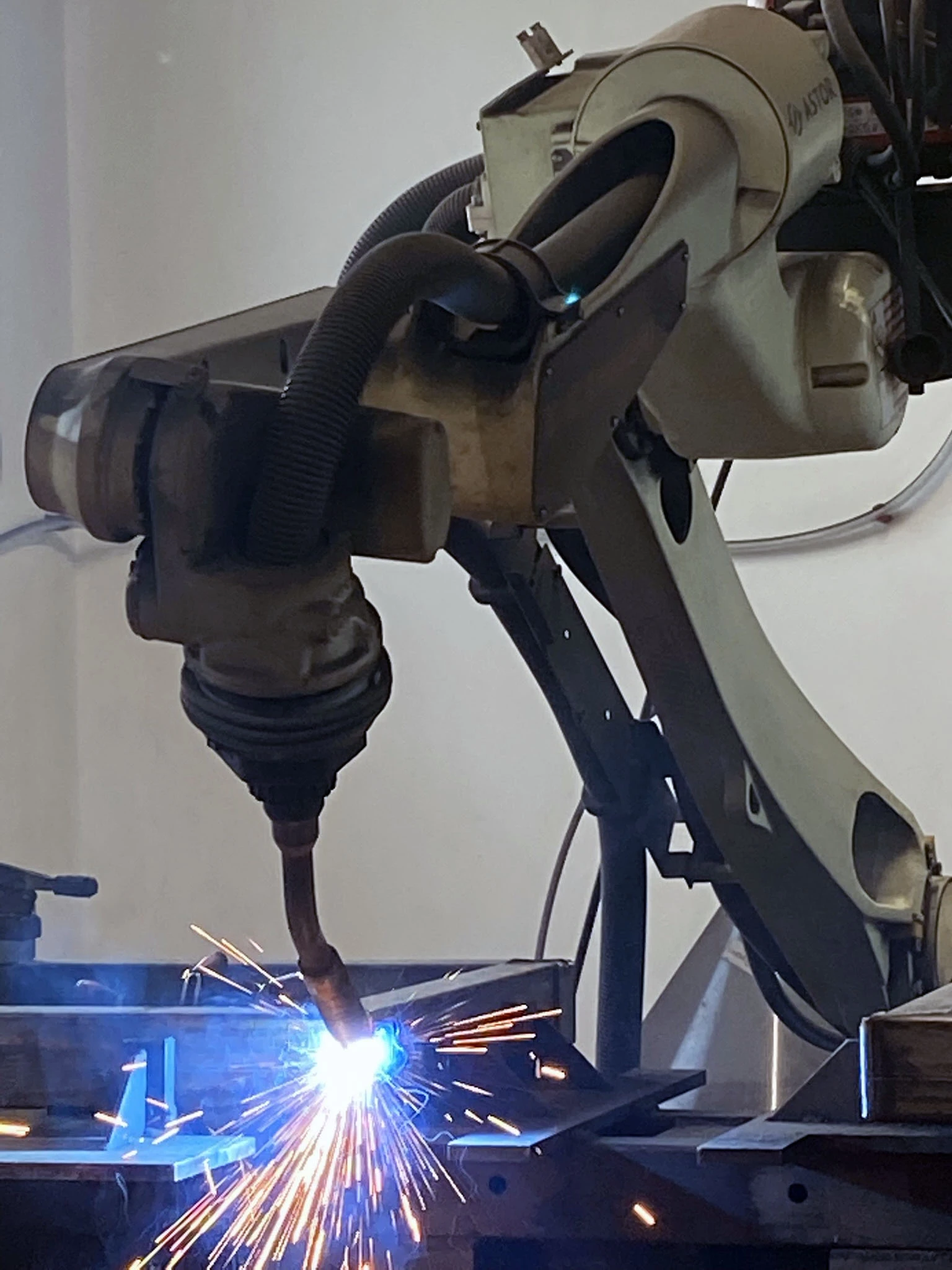

The robotised welding station represents a revolution in the efficiency and effectiveness of welding processes. Thanks to its use, the time in which a product is welded is significantly improved. This opens the door to achieving higher quality and increased productivity in production processes.

Robotic welding – the optimum solution

In the robotic welding station, the components from which the finished products are made are precisely inserted into specially prepared dies placed on swivels. They are then clamped in place, thus ensuring that they do not move or change position during welding. This technology eliminates any possibility of human error, which can lead to faulty joints or other imperfections.

Repeatability and precision with robot welding

Welding robots result in highly repeatable and aesthetically pleasing welds. The robots are programmed to perform each weld point with extreme precision and uniformity. As a result, every product manufactured with this system has identical, perfectly executed joints, resulting in an aesthetically pleasing appearance and high quality.

THE BENEFITS OF ROBOT WELDING:

|

Repeatable elements

|

|

Aesthetic joints

|

|

Technically well-made connections

|

Why are robot-welded products better?

- The advantages of robot welding are numerous and contribute significantly to the quality, efficiency and safety of the welding process. Here are some of the most important advantages:

- Precision and repeatability: welding robots are programmed to perform welds with extreme precision and uniformity. This ensures that every weld point is identical, resulting in excellent quality and repeatable joints. This eliminates human errors that can occur with manual welding.

- Excellent aesthetics and joint quality: Welding robots ensure aesthetically pleasing and technically perfect joints. Precise control of welding parameters, such as temperature and arc power, produces perfect joints that meet high quality standards.

- Multitasking: welding robots can be programmed to perform different types of welds and work with different materials.

All these advantages translate into greater efficiency, quality and competitiveness in the welding process, benefiting customers.

Interested?

Contact us